Company Profile

MATTECH, s.r.o. (Ltd. company) was established by its present owner from the very beginning in 1992. Since then, the company has been successfully extending its production programme, whose core lies in the proposal, calculation, production and services of flow meters with throttling devices which are in compliance with EN ISO 5167-1 up to 5 international standards.

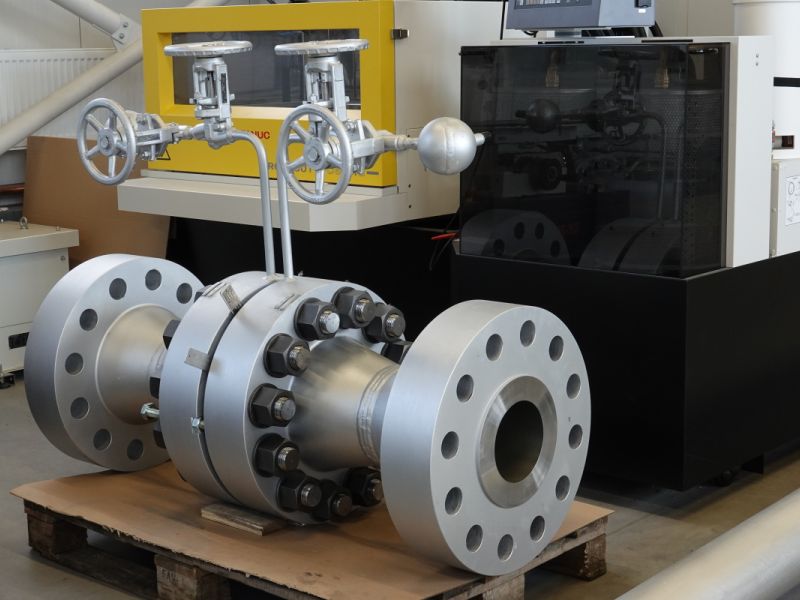

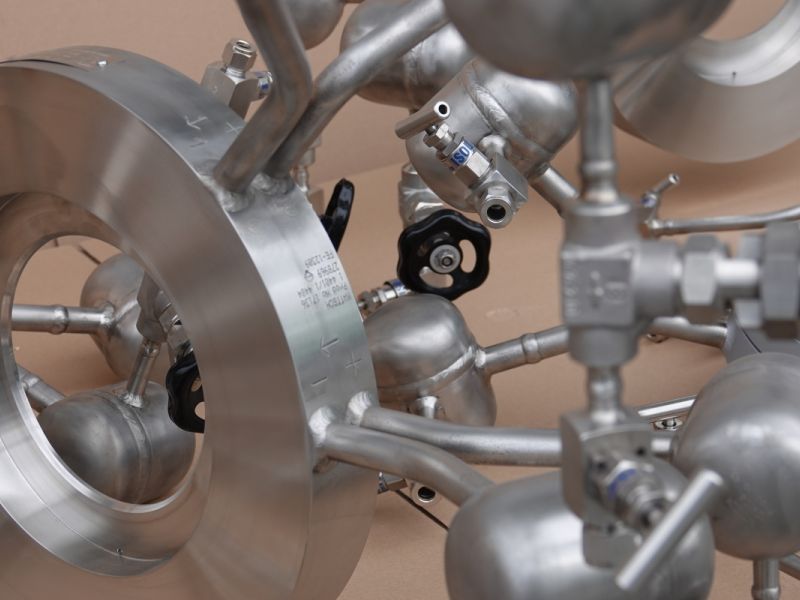

In the course of two decades, the company’s production programme has been extended to production of separation, mud-discharge and condensation vessels, flow straighteners, restriction orifice plates, multivariable restriction orifice plates, special orifice plates and plate discs, welded-on pieces, fittings, chambers for level measurement, steam coolers, and other components for mechanical parts of metering circuits.

We have developed meter tubes with flow meters, such as eccentric orifice plates, critical nozzles and multi-nozzles. We have also developed meter tubes with integrated orifice plate for measurement of flow in small diameter pipes.

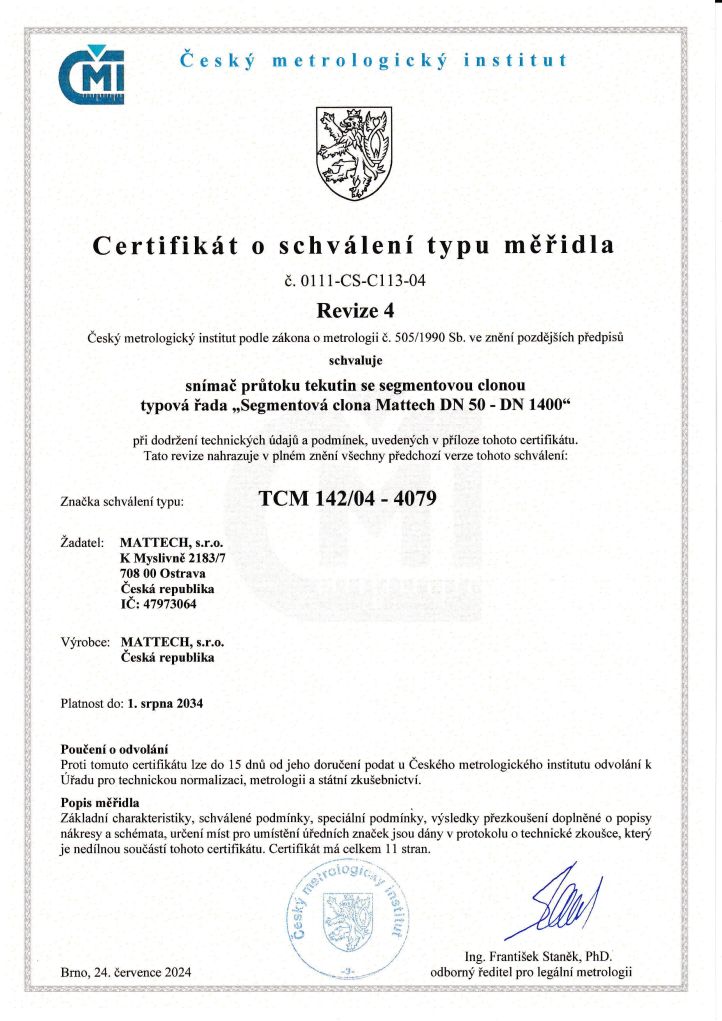

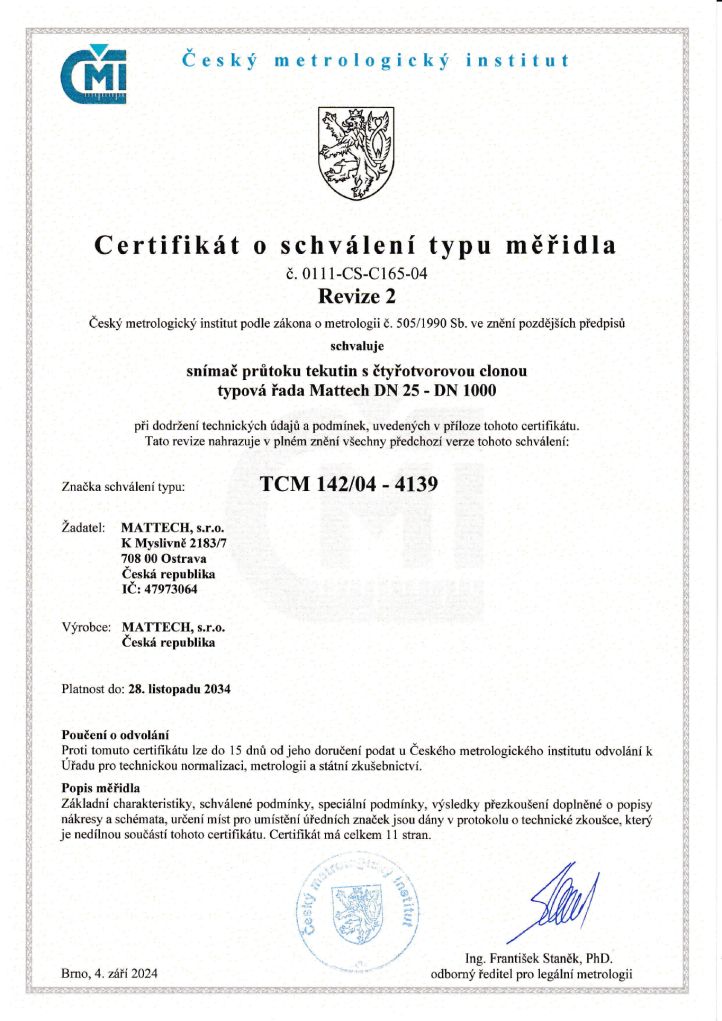

We have been working on development as well as wider use of segmental and multi-bore orifice plates across all industries. We have been developing our own technological processes for proposal, calculation and production of special orifice plates and special nozzles both for industrial use and testing.

MATTECH s.r.o. is focused on human and professional development of its employees aimed at high degree of independence, professionalism and customer mindedness. The company employs highly qualified engineers, technicians skilled in measurement and control as well as experienced workshop operators. Our employees are trained at new technologies and manufacturing processes every year, we put emphasis on developing their human and professional skills, including supporting their leisure activities financially. Employees in production are trained at new technologies of machining and operation of CNC machines including regular work safety and fire protection trainings. Company’s management is aware that qualified and hardworking people with good morals is the key of the company’s success. For these reasons, much efforts, time and funds are paid to human resources.

Petr and Valentina Pavlicek

Wishing you good health and all the best

owner of MATTECH s.r.o. (Ltd.)

In spring 2003 MATTECH s.r.o., moved to its own premises with an area of 4, 000 m2, in which there are several manufacturing and administrative buildings with high quality technical background. These manufacturing facilities were extensively rebuilt in 2011–2013 and a new production hall was built, too. In 2015–2022 there were built further manufacturing halls incl. preparation areas and new parking places on its premises.

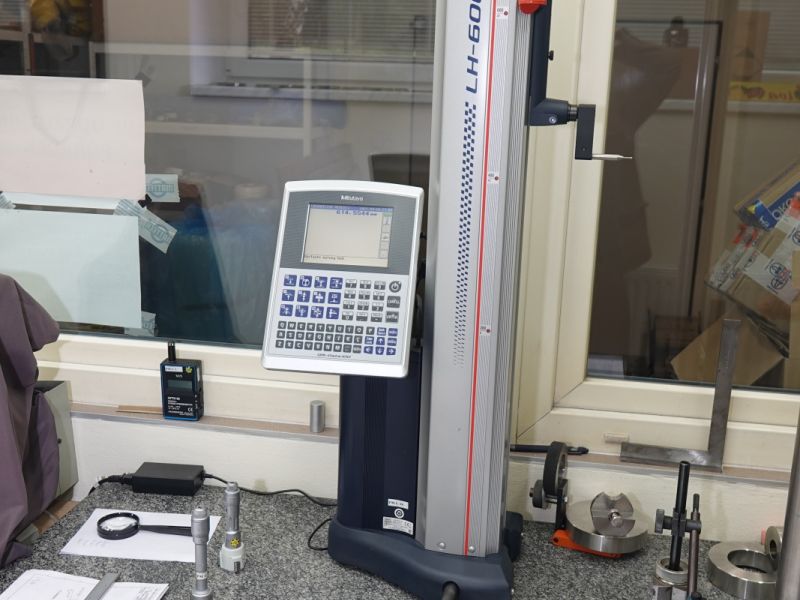

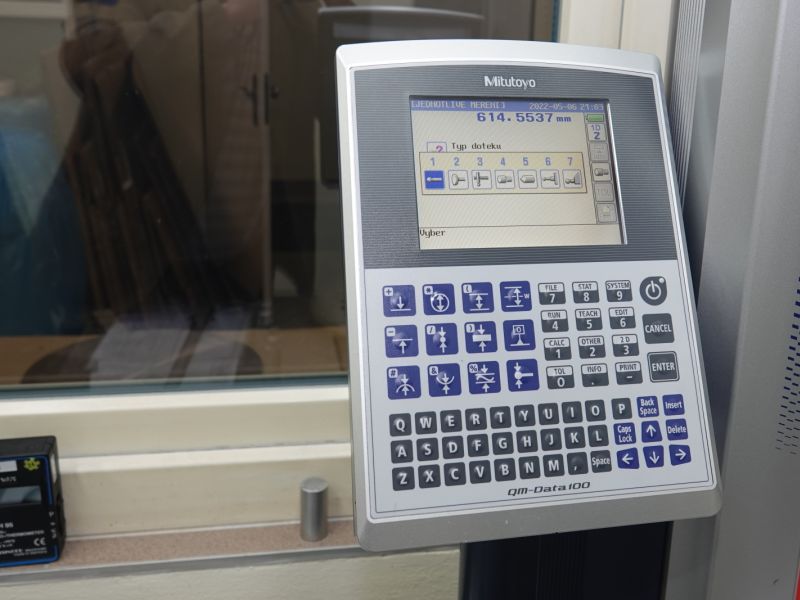

The important part of MATTECH s.r.o. is its own development focused on new products and new innovative manufacturing technologies aiming at increasing competitiveness of the meters at local and international markets. Design and construction are made in 3D construction CAD programs from Autodesk. Experienced staff and junior engineers working on design and construction prepare data for production and they take part in maintaining high quality of products. Calculations and designs of measuring circuits are used as technical support for design, supplier and assembly organizations. Flow meters are manufactured and supplied in compliance with ČSN, ISO, ANSI, ASME, GOST standards, or according to specifications and requirements of the customer.

Parallel with the construction of new facilities and expansion of the production program of MATTECH s.r.o. new CNC machines and technical equipment are being purchased. At the company´s area there are modern halls equipped with forklifts and lifting equipment including cutting materials by high-pressure water jet cutter. In the manufacturing area there are all essential up-to-date CNC and electro-erosive machines for production of all flow meter components with machining range from micro dimensions to dimensions exceeding one meter up to work-pieces of many tons. Manufacturing facility consists of storage, handling and assembly areas. The manufacturing facility is has its own certified welding shop with staff certified for welding pressure components and parts for nuclear power stations. The whole manufacturing process is completed in our coating shop and pressure testing laboratory for test pressures up to 800 bars. Concept of the production is focused on minimization of sub-supplies and cooperation aimed at ensuring high quality of our products.

A large part of our products is supplied to petrochemical industry, classical energy resources, power stations for supercritical parameters, nuclear power plants, HVAC testing and laboratories. For many years we have been the leading manufacturer and innovator of the flow meters based on the principle of differential pressure both in our country and in abroad. We are cooperating on supplies of meters for research purposes and technical colleges and for measurement of environmental limits for fuel combustion. Individual approach to each customer, flexibility and high quality service guarantees your satisfaction.

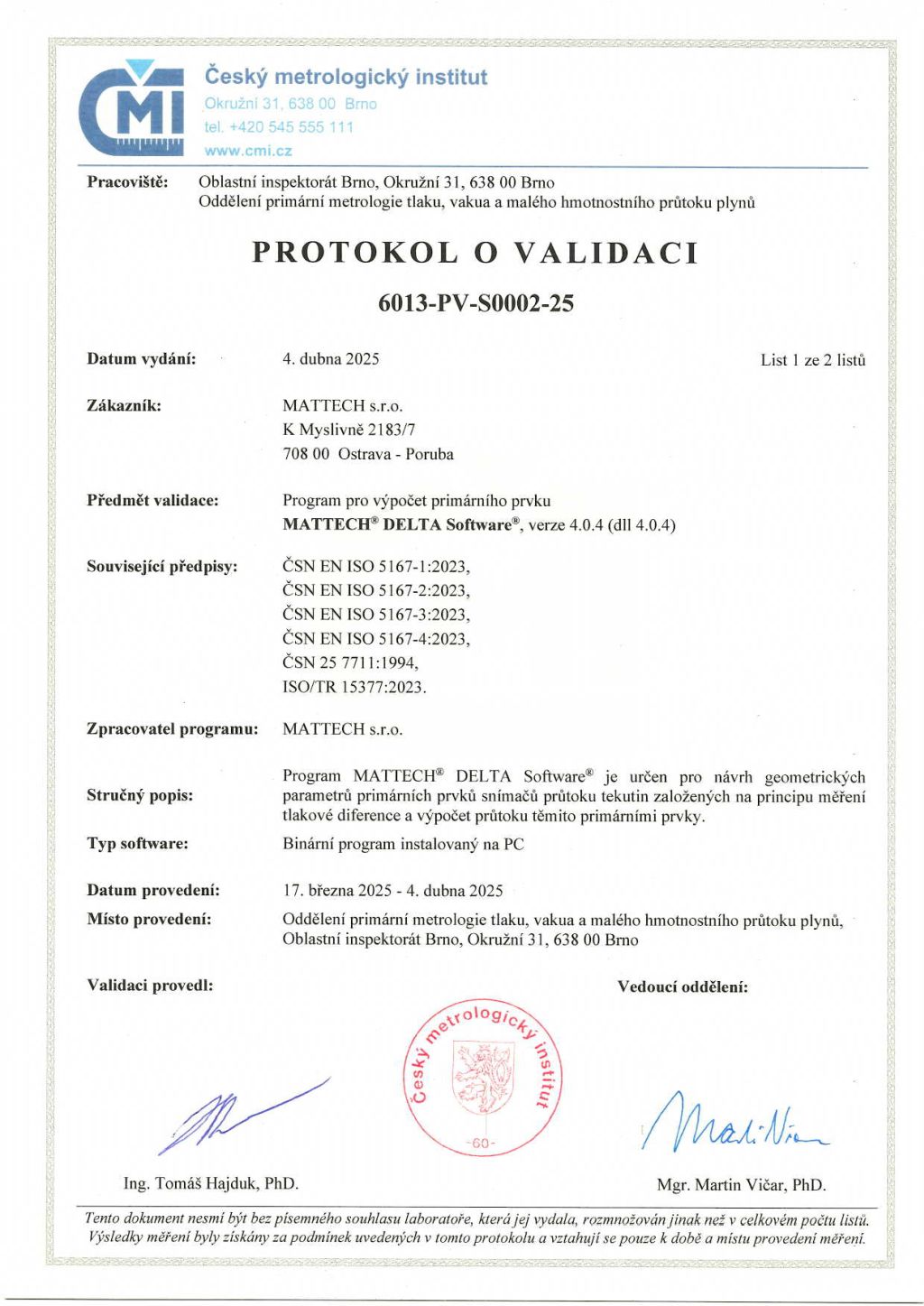

In 2015 MATTECH s.r.o. purchased and developed unique calculating computer program MATTECH® DELTA Software® for easy and quick designing and calculation of primary devices for the measurement of gas, vapors, water and fluid flow. This software provides the technicians and other users with high flexibility as well as with uncommon possibilities compared to other calculation programs. It has been developed for 20 years and its functionality was verified in many engineering and construction companies. Updated versions of MATTECH® DELTA Software® were verified by years of experience and approved by the Czech Metrology Institute. For more information about the software see page MATTECH® DELTA Software®.

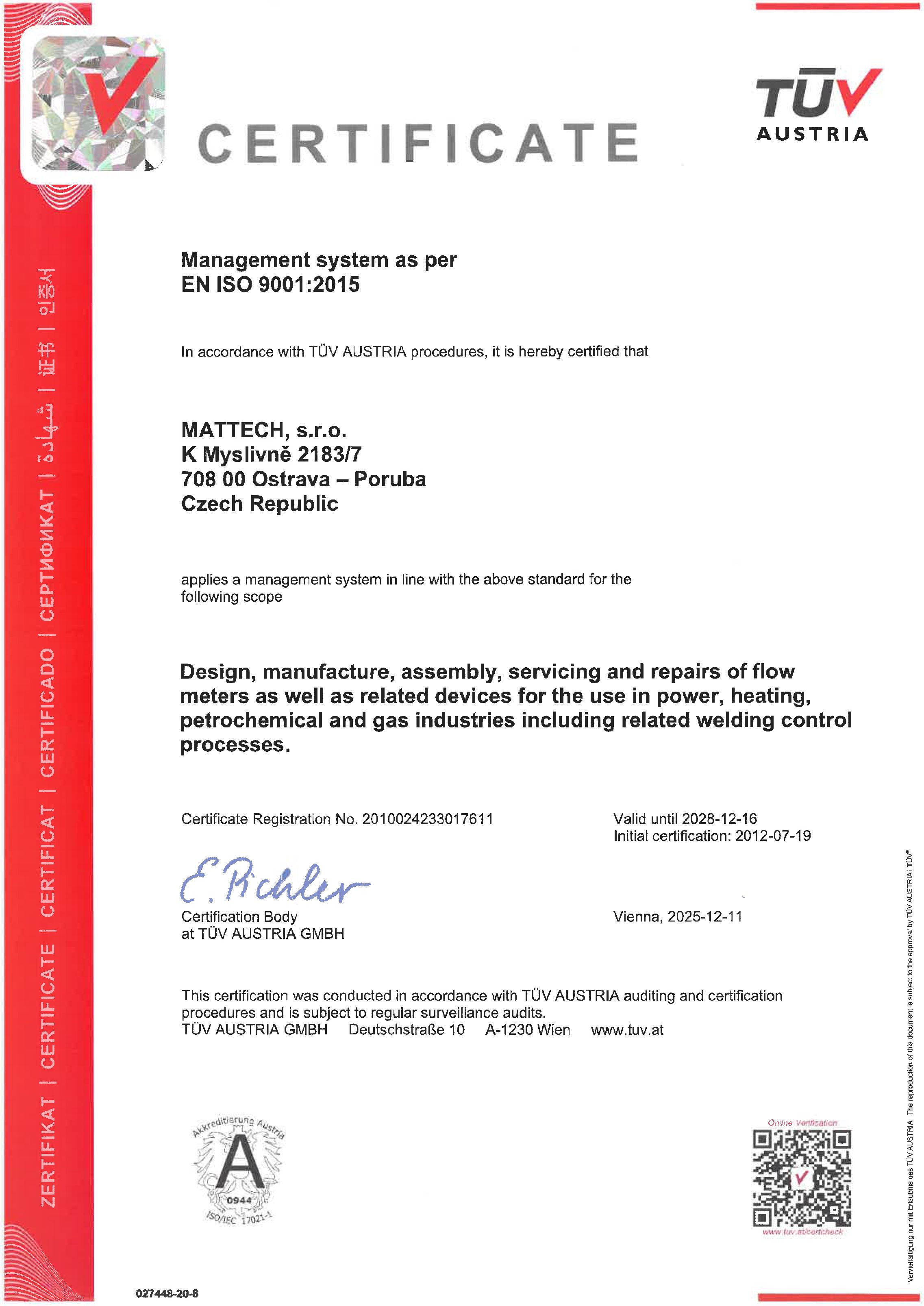

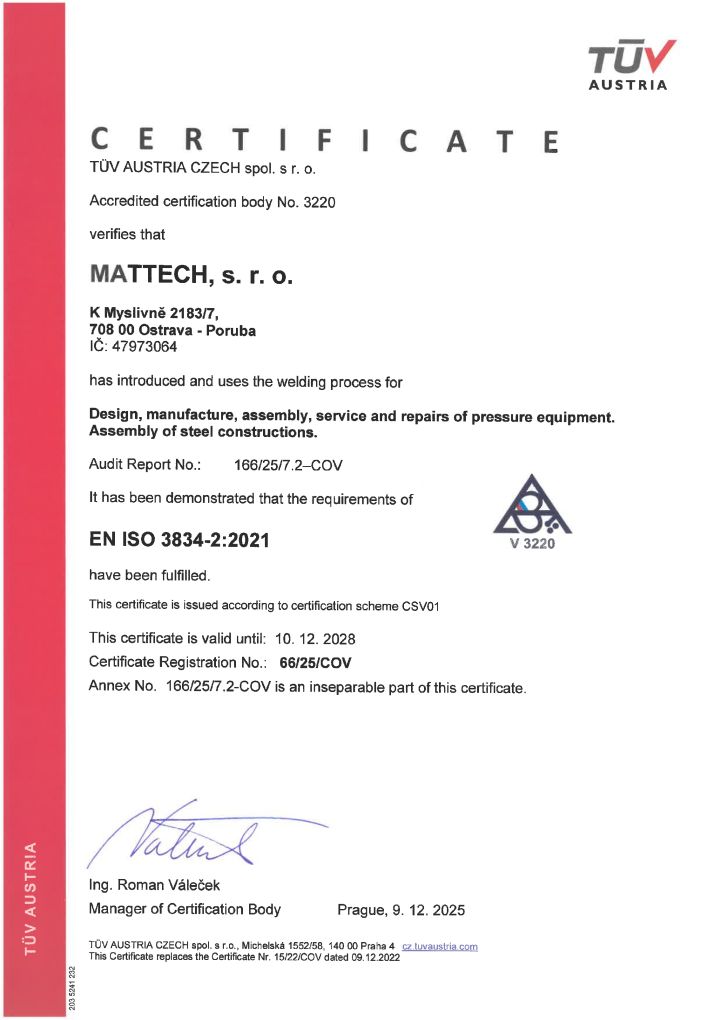

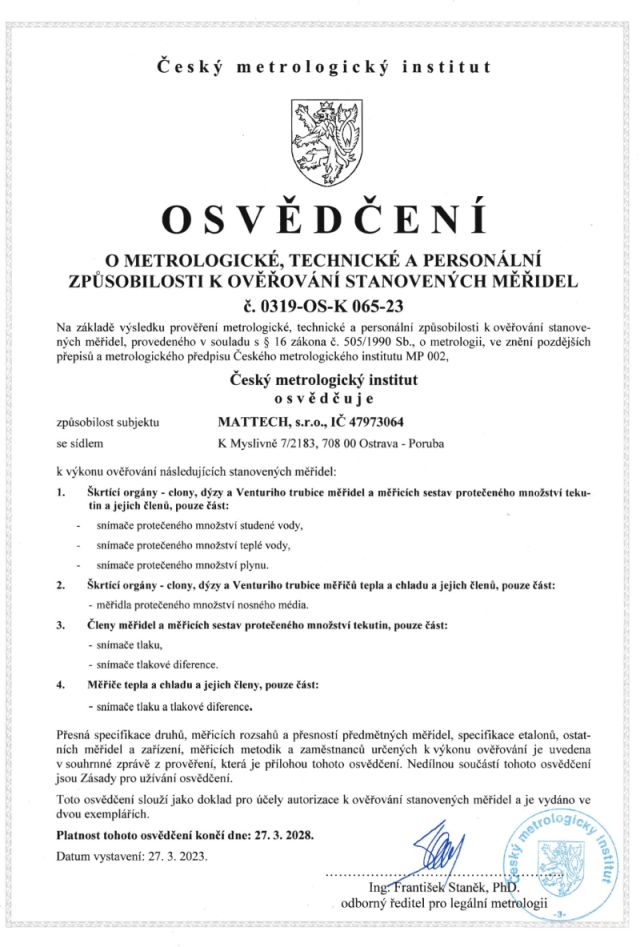

Quality Management System and Certifications

In 2001 MATTECH, s.r.o. implemented the quality management system and was successfully certified by the British company Lloyd´s Register Quality Assurance. In the course of 2002–2003 the company was fully certified for manufacturing the pressure components according to Directive PED 97/23 EC.

In 2012–2014 the company was successfully certified on welding and manufacturing of pressure components for nuclear power stations. Quality management systems as well as pressure components quality management is verified every year by the internal and customer audits and it is also regularly certified by auditing company. In the course of 2016 the quality management system is being re-certified in compliance with ISO 9001:2015 standard and amended Directive for manufacturing pressure components PED 2014/68/EU.

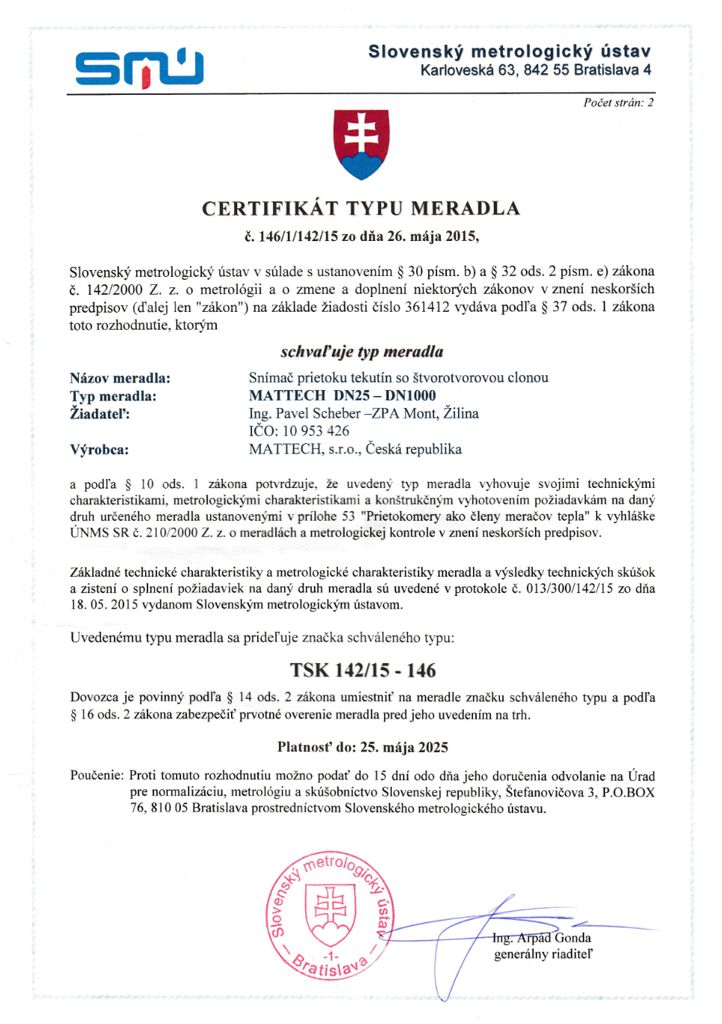

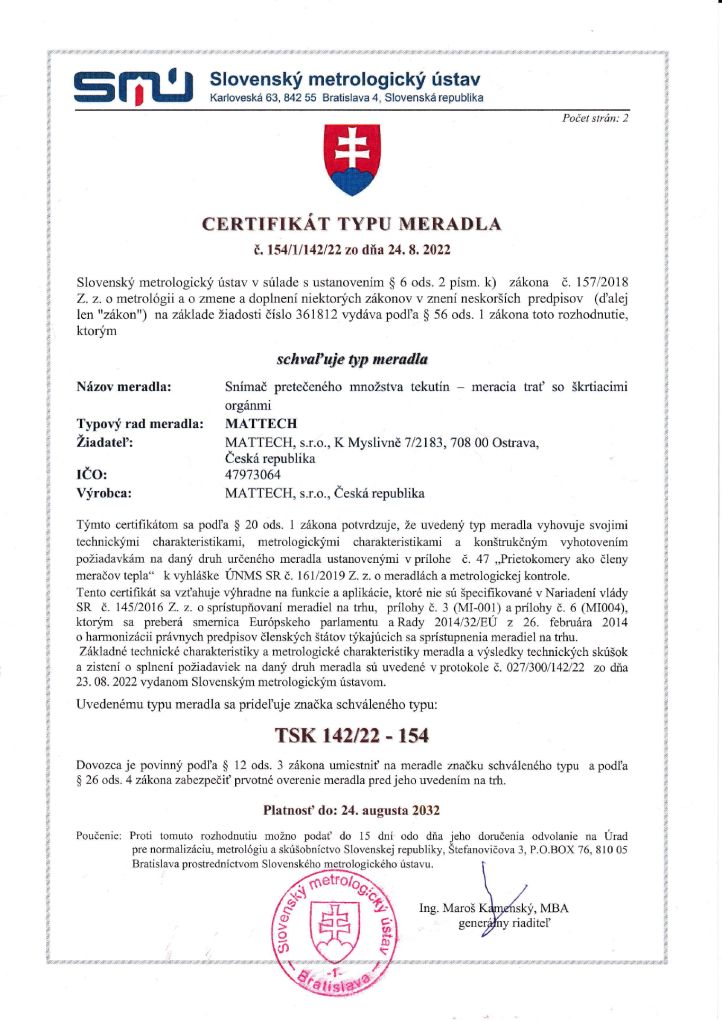

Together with the development of manufacturing programme we made efforts to ensure quality of our products, not only from technical point of view, but legislation as well. Our company obtained new permissions to its specialized activities valid within European Union.